- Support Mechatrolink-III serial communication interface

- Fulfill Every Application-Works with Various Servo Drivers

- Integrate High-Speed Upper Serial Communication Interface

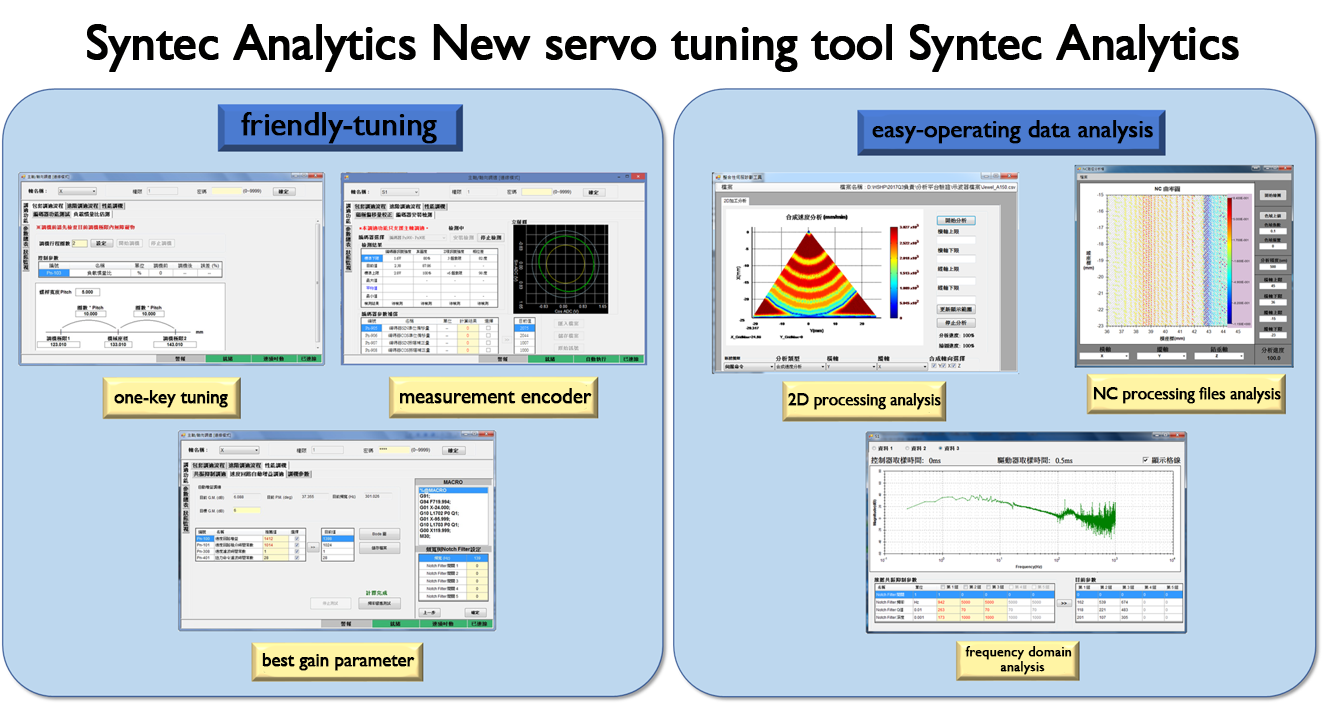

- Supports Multiple Functions of Servo Drivers-New servo tuning tool Syntec Analytics

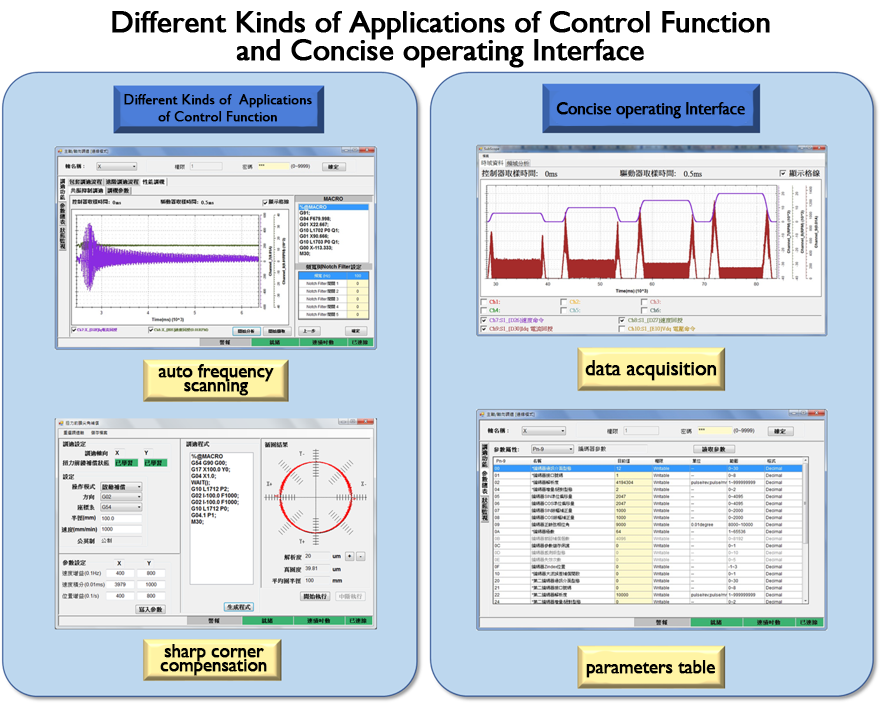

- Different Kinds of Applications of Control/ Function and Concise operating Interface

- Communication rate up to 100Mbps, transmits all kinds of controller information in a faster way (ex. Location of device, communication rate)

- Transmission distance up to 100 meters between devices without a repeater

- Adapting different format of data simultaneously, choosing the most appropriate one for a device-Support M2 and M3 in the same time, integrate full series products of Syntec

Fulfill Every Application

- SPD series supports up to 18.5 kW.-SVD series supports up to 3 kW.-Supports 24 bits absolute encoder communication interface

Work with Various Servo Drivers

- Meet various applications of machine tools like lathe, tapping machine, vertical machining center, and engraving machine-Built a high resolution, high precision encoder to reach perfect processing performance

Integrate High-Speed Upper Serial Communication Interface

- Integrate Syntec controllers vertically to reach high-speed upper serial communication in total system.

- Host computer integrates servo information and provides the function of monitoring and revising parameters.

- The vertical integration of the upper and lower positions provides high-speed spindle positioning and other special features

Supporting Multiple Functions of Servo Drivers

- Driving control of permanent-magnet synchronous motors and induction motors.

- Driving control of linear motors.

- Driving control of 4-axis direct drivers.

Syntec Analytics New servo tuning tool Syntec Analytics

- Friendly-tuning, including semi-automatic resonance suppression, providing suggested suppression points

- Measurement encoder to ensure the function of feedback and control

- For other CNC machines with Syntec encoders, we provide encoder compensation to eliminate installation error.

- Auto gain tuning, calculating best gain parameter

- Evaluate processing files of 3 axis simultaneously

- Evaluate and simulate the section view of workpiece for detailed-observing, and provides picture of speed/acceleration to clarify problems

Different Kinds of Applications of Control Function and Concise operating Interface

- Software upgrading, parameters setting, and data retrieving are functions provided. -Built auto adjustment function. -Provides several applicants including Bode plot analysis.

Inquiry - Syntec Servo